Not just blankets!

Witney was well known for its wool products from at least the early Middle Ages, and by the 17th century it was famed for its blankets. Down the years the different blanket makers and companies were often involved in other trades and the making of things other than blankets through necessity, enterprise or tradition. Here are some examples:

-

The underside of a leather horse collar showing the collar check

lining.

- Before the 17th century Witney's main trade was undyed woollen

broadcloth and although some of this was made into blankets it

was also used for making water-resistant clothing such as coats.

In 1814 the blanket maker Edward Early received this order from

Lord Sherborne:

'Mr Early, I want a warm great coat very much and I should like

one of a light warm Witney Blanketting and a light brown colour;

the last I had was so heavy I could not wear it. I should like

to know the width and price. If you will execute this commission

I will send you a brace of Hares.' [1]

-

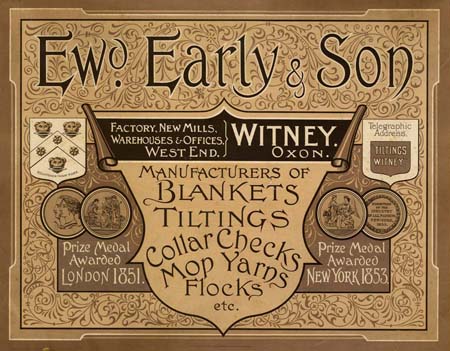

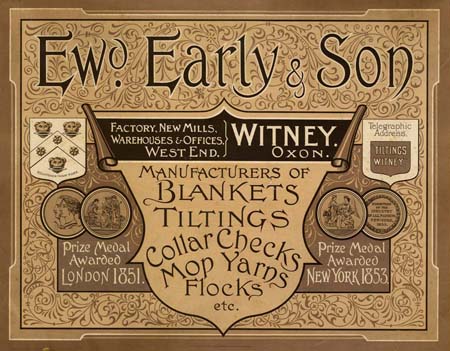

Edward Early and Sons' advert listing tilts, horse collar check

and mop yarn.

-

The two Misses Busby photographed at the closing of the

mop-making department of Edward Early's factory at 55-56 West

End in 1960.

- Before the days of factories it was common for wool spinners,

carders and others connected with the weaving trade to take on

farm work at harvest and other busy times. It seems that around

Witney, though, the weavers themselves rarely got involved with

agricultural work as they appear to have been quite highly paid

compared to other textile workers in England [2]. As the demand

for woollen cloth fluctuated many people found it wise to have

two or more occupations, such as the 17th century Witney

innkeepers who also had looms, wool and yarn listed among their

possessions.

- It was not unusual for people plying a trade in the weaving

industry to have a second wool-related occupation, such as

clothiers who also owned fulling mills, and dyers who were also

sheep farmers. In 1692 the wealthy blanket-maker Joseph Selman

owned a sheep-shearing shop, weaving shop, dye shop and wool

house, as well as tenter racks for drying cloth at New Mill, so

he would have been involved with most stages of production. In

the 18th and 19th centuries the blanket making family of

Marriott were also cloth dyers (and later they entered the coal

trade).

-

A rug pattern from Early's, used to create the punched cards

that controlled the Jacquard looms.

- Pritchett and Webley inherited a bicycle frame brazing business

with their lease for Worsham Mill in the 1890s! They were to set

up business there making blankets, mops and tilts (a venture

that was unfortunately to last less than 20 years), as well as

cycles [4].

-

A 'Warlord' brand Fiberwoven carpet tile made by Early's, 1970s.

|